Key features for Jenuin YHF welding cable

1. Voltage & Weather Resistance

Utilizes pure natural rubber insulation for balanced electrical conductivity and safety performance.

Engineered to withstand high-voltage stress and extreme weather fluctuations.

2. Flexibility & Bend Performance

Superior flexibility, ideal for high-frequency movement/twisting in welding operations.

3. Abrasion & Mechanical Resilience

Elastomeric outer sheath provides:

✓ Tear resistance (≥15 N/mm tensile strength)

✓ Enhanced abrasion resistance (tested under 10,000+ friction cycles)

✓ Crush resistance for harsh worksites.

4. Chemical & Environmental Durability

Operates reliably in hazardous conditions:

✓ High-temperature exposure (up to 90°C)

✓ Immersion in boiling water, mud, oils, and acid/alkali solutions (pH 2-12).Certified oil/solvent resistance (compatible with ISO 1817 standards).

5. Compact & Lightweight Design

Reduced diameter-to-weight ratio simplifies handling in confined spaces (e.g., shipyards, construction rigs).

The YHF Welding Cable Parameter

Cross-sectional Area (mm²) | Average overall diameter (mm) | Core | Reference weight (kg/km) | Conductor Resistance 20ºC Max (Ω/km) | |

16 | - | 9.5 | 1 | 235 | ≤1.15 |

25 | - | 10.5 | 1 | 350 | ≤0.727 |

35 | - | 12.0 | 1 | 490 | ≤0.524 |

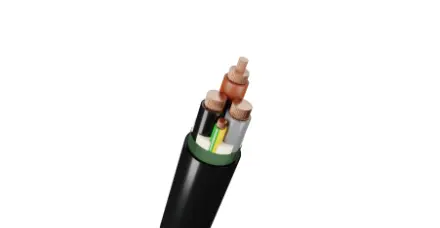

2x16 | - | 15.2 | 2 | 680 | ≤1.15 |

3x16 | - | 17.8 | 3 | 1020 | ≤1.15 |

3x25+1x16 | - | 24.5 | 4 | 1650 | ≤0.727 |

Description Of YHF welding cable

Rated Temperature: 90℃

Rated Voltage: 300/500V, 450/750V

Reference Standard: IEC 60245/BS EN50525-2-81

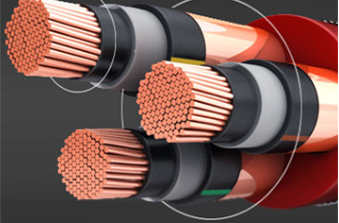

Conductor: Shaped and circular stranded copper conductors

Insulated: ethylene propylene rubber (EPR)

English

English  français

français  Deutsch

Deutsch  العربية

العربية  tiếng việt

tiếng việt  ไทย

ไทย  čeština

čeština  Indonesia

Indonesia  Eesti

Eesti  български

български  slovenčina

slovenčina

+

+

+

+